|

|

2005 July — Vol. XIV, No. 5 |

|

Current Issues |

|

|

|

EOM July 2005 > Departments > Interview

Remote Sensing For Pipeline Safety: A Conversation with Dan Brake

Adena Schutzberg

Figure 5: Dan Brake Click on image to see enlarged.

Dan Brake's title is Director, Active Imaging Solutions, Space Systems Division, ITT Industries. Last fall the company announced a new service, Airborne Natural Gas Emission LiDAR (ANGEL), that uses active imaging to detect natural gas leaks from pipelines. A small plane flies over pipelines, sensing for gas in real time. In addition to alerting those on the ground of situations in need of immediate attention, each mission delivers GIS datasets, maps, and integrated reports to pipeline companies. The idea is to catch small problems, before they become larger ones.

LiDAR, but with a Twist

I first asked Brake to explain how the LiDAR I'm familiar with, that's used to capture bare Earth topography, compares to the LiDAR used for gas detection. He explained that "LiDAR for elevation data is built on a laser frequency that is minimally affected by atmospheric conditions. Further, LiDAR topography missions measure the return time of the pulse — when each pulse returns to the sensor. That time difference provides information on the different objects the pulse might hit and bounce off on the way down — tree cover, plant cover, and finally the ground."

Figure 1: Flight Envelope —Conceptual view of the ANGEL aircraft capturing survey data along pipeline right-of-way. Click on image to see enlarged.

The LiDAR used in ANGEL is based on Differential Absorption LiDAR (DIAL). Instead of using a single frequency, ANGEL's DIAL sensor uses three different ones. Each one is "tuned" for something different. The first one is essentially the same as those used for topographic collection: it is unaffected by atmospheric interference and is used as the system's reference. The second one is tuned to be absorbed by a specific gas, methane. The third one is tuned to be absorbed by a second gas, ethane.

Unlike the use of time to measure distance in "traditional" LiDAR, ANGEL's system measures how much energy each frequency returns and compares them to one another. When only a "little" energy from frequency 2 comes back, there's quite a bit of methane present. If all the frequency 3 energy comes back, there's no ethane below. While that's the general concept, the measurements are far more specific.

The next question put me back in high school chemistry: Why measure both methane and ethane? Methane is naturally occurring, popping up in swamps, farms, landfills, and other places where living things decay. Methane, Brake points out, "is the seventh most abundant gas in the atmosphere, so, detecting just methane won't necessarily identify natural gas." Ethane is not as abundant, and is most commonly found in, you guessed it, natural gas. So, ANGEL is designed to find the two together, which raises the confidence of finding natural gas.

Continued below ...

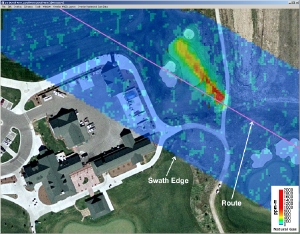

Figure 2: Zoom In &mdash10x enlargement of natural gas plume. ITT ANGEL System has detected emissions of natural gas. The plume is integrated with color imagery and GIS coordinated to provide the precise location. Click on image to see enlarged.

The sensor is only part of the story. "The whole system weighs 2,000 pounds and includes: the three laser DIAL sensor; a pointing, tracking and scanning system; airborne GPS, inertial measuring technologies, and navigation tools; a high resolution digital mapping camera; a high resolution video recorder; and a suite of storage and communications systems." The DIAL data is analyzed onboard and if a threshold value is exceeded, an alert is sent immediately to the pilot. Back on the ground data is certified and developed into GIS layers, maps, and integrated reports for the clients. The plane carrying the sensor typically travels at 1,500 feet above the pipeline right of way and can cover 800-1,000 miles of pipeline per day.

New Legislation for Pipeline Safety

Brake would certainly agree that the technology is interesting, but he gets most animated when addressing why it came about. He points to two serious accidents in recent years that prompted new federal legislation for pipeline safety. In Bellingham, Washington in 1999, a gas leak introduced flammable liquids into a river. The resulting fire killed three children. In Carlsbad, New Mexico in 2000, a natural gas pipeline explosion killed twelve. These made the news and, like serious aircraft accidents, sparked public interest in enhanced government safety regulations.

Figure 3: Zoom Out &mdashITT ANGEL System has detected emissions of natural gas. The plume is integrated with color imagery and GIS coordinated to provide the precise location. Click on image to see enlarged.

That led to the Pipeline Safety Improvement Bill in 2002, which was signed by President Bush in December of that year. Brake notes that it was "one the largest overhauls of energy safety policy in the United States, ever." He points to three key elements of the legislation. First, pipeline operators are required to implement integrity management plans to insure the safety of the pipelines. Special emphasis is to be on High Consequence Areas (HCAs). HCAs are those areas that would suffer significant damage in event of a leak. These might include areas with schools, hospitals, and high populations. Low consequence areas, where pipelines cross under farm fields far from population centers, need to be examined, too, just less frequently. Second, the legislation significantly increases penalties for safety violations, with some being as high $1,000,000. Third, the bill requires better training of workers and enhanced notification of environmental and safety issues to the public. Brake put it this way: "The Bill insured there is no excuse the companies could use to avoid updating processes and technologies."

How and How Often to Survey Pipelines

How often does the legislation say the pipelines need to be examined? Brake noted that there are in fact two types of examinations — called leak surveys and patrolling. In a leak survey, the goal is to specifically look for leaks with instrumented equipment. Pipelines are classified into one of four, numbered classes. Lines that run through high consequence areas are 4s, those in low consequence areas are 1s and 2s, and those in between are 3s. Leak surveys for class 1 and 2 lines are required at least once a year, for category 3 twice a year, and for category 4 four times per year.

Patrolling essentially means looking at the pipeline corridor and the area around it to see whether there are potential "3rd party encroachments." That's a fancy term for construction equipment that might hit the pipe. Since 2002, state One-Call and DigSafe programs have been in place, but that doesn't avoid the need for patrolling. Patrolling, Brake is quick to point out, is reactive. "By the time someone sees the backhoe near the pipeline, it may be too late." Patrolling is required, at a minimum, with the same regularity as leak surveys for the four categories.

If ANGEL is the "new" technology for leak surveys, what was the old technology?

Figure 4: Plume Contour Map &mdashThe ANGEL system detects, quantifies, images and maps concentrations of both methane and ethane gas. Click on image to see enlarged.

Essentially, Brake explained, current leak surveys involve a crew of people literally walking the length of the pipeline with lunchbox-sized gas sensors. During the walks, which typically have 3 people per crew, the walkers do more than just look for leaks. They check the state of valves, visually inspect the right of way, check the security of fences, confirm safety signage, etc. Still, with a crew covering between 5 and 10 miles of pipeline per day, the work is slow, labor intensive, expensive, and subject to human error. Additional challenges are getting the workers to the locations, which are often remote and in rugged terrain, and ensuring that private property owners provide access. (There are easements, but there can be discussions that slow the work down.) Flying with a sensor eliminates many of the limitations, though it does not perform all of the tasks of walking crews. Still, the quicker data collection, the ability to fly over rough terrain, and the automated measurements which sidestep the human factor, all appeal to those in the pipeline industry. Brake is pleased, and frankly a bit overwhelmed by the fact that "every player in the industry approached about the solution was supportive of ITT's efforts. No one said, 'This is a bad idea.'"

Everything You Wanted to Know About Pipelines

Since I don't see too many pipelines in my day-to-day life, I asked Brake to describe where they are and what they look like. Brake himself is still pretty amazed by the number of natural gas transmission pipeline miles in the United States: 300,000 (the distance from the Earth to the Moon), 90 percent of which are underground. "Typically they are at least 3 feet underground, below the frost line, to prevent frost heaves. That also means that other activities, agriculture, for example, can occur above them." The pipelines, he continued, come in three types. "The gathering lines take the gas from the wells and fields to the plants. They are under low pressure and have fairly small diameters. At the plant, the gas is cleaned of impurities and then sent out under high pressure via transmission lines. These are large, 24" - 48" inches in diameter, and can support pressures up to 1,500 PSI (For comparison, my road bike's tires are inflated to 100 PSI.) The transmission lines might feed large gas users, such as foundries, directly, but most end users receive their gas via smaller, lower-pressure distribution lines. The change-over from the high-pressure transmission lines to the lower-pressure distribution lines occurs at the city gates. It's also at the city gates, by the way, that the 'rotten egg smell' of the gas, designed to protect the public, is added. The gas in the majority of transmission lines is odorless." It turns out that the largest five or six transmission companies own 50 percent of the pipeline miles in the United States. They have familiar names like Kinder Morgan, Williams, and El Paso Energy.

Brake is most excited about taking this remote sensing technology and applying it to a "real problem." While there are other technologies that also "keep an eye on" pipelines, notably SCADA (Supervisory Control and Data Acquisition Systems), a sophisticated software system that takes measurements and collects data along the pipeline, ANGEL provides a different and significantly more sensitive way to proactively monitor the lines — and provides accurate, quantitative data very quickly. As Brake points out, ITT has a long heritage and strong reputation for developing innovative and reliable remote sensing technologies, particularly for government customers. It was only natural to bring this expertise to the pipeline and gas industry, where safety and security are of equal importance. The technology was announced publicly just last fall and the company is still running trials. If all goes well, the service will be offered later this spring. ![]()

About the Author

Adena Schutzberg was the editor of EOM from April 2004 to January 2005.

|

|

|

©Copyright 2005-2021 by GITC America, Inc. Articles may not be reproduced, in whole or in part, without prior authorization from GITC America, Inc. |